Spiral miter bevel gear

Please get in touch with us for details.

Mail:[email protected]

Bevel Gear

Bevel gears are an essential component in many mechanical systems, providing a means of transmitting power and motion between intersecting shafts. These gears are characterized by their conical shape, with teeth cut along the angled surface. The teeth on bevel gears are designed to mesh together, allowing for smooth and efficient transfer of torque between the input and output shafts.

At their core, bevel gears are just one type of gear in a larger family of machinery components known as gears. Gears are essential in many mechanical systems, allowing for the efficient transfer of power and motion between rotating components. Different types of gears are used for different applications, with bevel gears being particularly well-suited for systems where the input and output shafts intersect at an angle.

One of the primary benefits of using bevel gears is their ability to transmit power and motion between intersecting shafts without the need for additional components such as universal joints. This makes them ideal for a wide range of applications, including automotive, aerospace, marine, and industrial machinery.

Bevel Gear Specifications

|

Module

|

M0.3-M10

|

|||

|

Precision grade

|

DIN5, DIN6, DIN7, DIN8, DIN10

|

|||

|

Pressure angle:

|

14.5 degree, 15 degree, 20 degree

|

|||

|

Material

|

C45 steel, ,304SS, 316SS, 20CrMo,40Cr, brass, nylon, POM, and so on

|

|||

|

Heat treatment

|

Hardening and Tempering

High Frequency Quenching

Carburization etc

|

|||

|

Surface treatment

|

Blacking, Polishing, Anodization, Chrome Plating, Zinc Plating, Nickel Plating

|

|||

Bevel Gear Benefits

High strength and durability: Bevel gears are made from strong materials, such as steel or stainless steel, and are precision-machined to ensure that they can withstand high loads and stresses. This makes them ideal for use in applications where there is a lot of wear and tear.

Smooth, quiet operation: Bevel gears have a helical tooth profile, which allows them to mesh smoothly and quietly. This is important in applications where noise is a concern, such as in machine tools or elevators.

High efficiency: Bevel gears are very efficient, meaning that they transmit a lot of power with very little loss. This is due to the smooth, quiet operation of the gears, as well as the high quality of the materials used.

Long service life: Bevel gears are designed to last for many years, even in demanding applications. This is due to the high strength and durability of the materials used, as well as the precision machining.

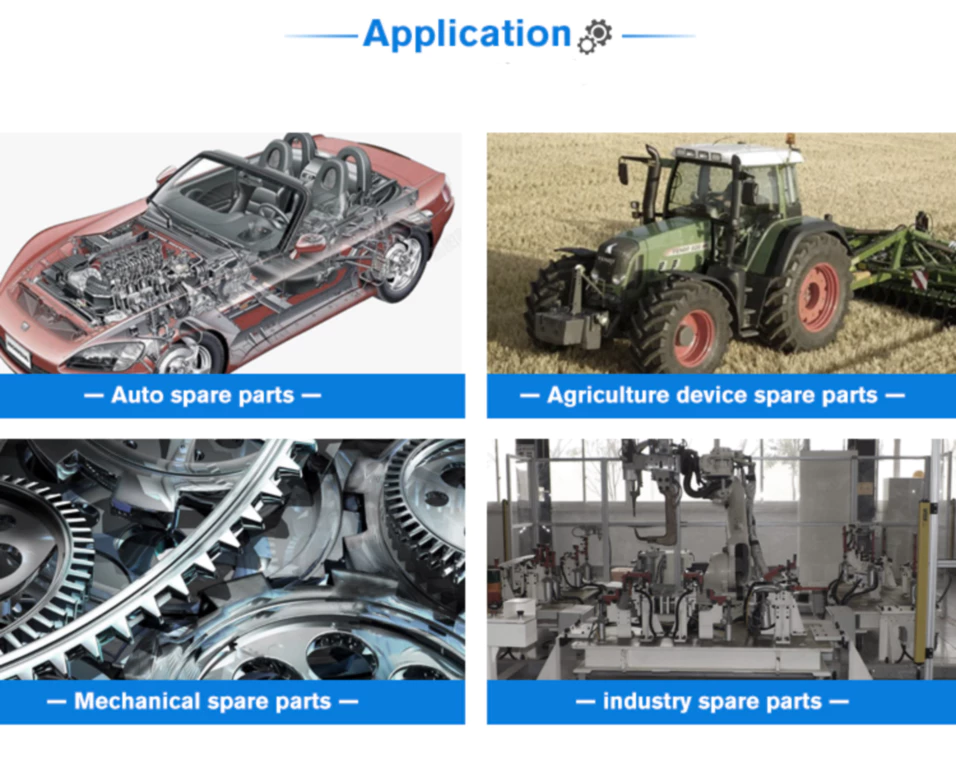

Uses Of Bevel Gear

Automotive transmissions: Bevel gears are used in automotive transmissions to transmit power from the engine to the wheels. The high strength and durability of bevel gears make them ideal for this application, as they can withstand the high loads and stresses that are generated during driving.

Machine tools: Bevel gears are used in machine tools to transmit power from the motor to the cutting tool. The smooth, quiet operation of bevel gears is important in this application, as it helps to reduce noise and vibration.

Construction equipment: Bevel gears are used in construction equipment to transmit power from the engine to the wheels or other moving parts. The high efficiency of bevel gears is important in this application, as it helps to save fuel and reduce emissions.

Wind turbines: Bevel gears are used in wind turbines to transmit power from the rotor to the generator. The high torque and speed requirements of wind turbines make bevel gears an ideal choice for this application.

Elevators: Bevel gears are used in elevators to transmit power from the motor to the hoisting mechanism. The smooth, quiet operation of bevel gears is important in this application, as it helps to reduce noise and vibration.

Robotics: Bevel gears are used in robotics to transmit power from the actuators to the joints. The high speed and precision requirements of robotics make bevel gears an ideal choice for this application.

Maintenance tips for Bevel Gear

Regularly inspect the gears for wear and tear. Look for signs of damage, such as chipped or broken teeth, excessive wear, or misalignment. If you see any signs of damage, have the gears repaired or replaced as soon as possible.

Keep the gears clean and lubricated. This will help to prevent wear and tear and keep the gears operating smoothly. Use a clean, light oil or grease to lubricate the gears.

Check the alignment of the gears. The gears should be aligned properly to ensure that they mesh correctly. If the gears are misaligned, they can cause excessive wear and tear.

Check the backlash of the gears. Backlash is the amount of play between the teeth of the gears. Too much backlash can cause the gears to chatter and wear prematurely.

Replace the gears as needed. Even with proper maintenance, bevel gears will eventually wear out and need to be replaced.

We are one of the best bevel gear manufacturers. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!